How Low Voltage Soft Starters Enhance Energy Efficiency in Industrial Applications

Table of Contents

- Benefits of Low Voltage Soft Starters in Reducing Energy Consumption

- Real-World Case Studies: Energy Savings with Soft Starters in Manufacturing

- Understanding the Mechanism of Soft Starters for Improved Motor Efficiency

- Comparative Analysis: Soft Starters vs. Traditional Starting Methods

- Future Trends: Innovations in Soft Starter Technology for Industrial Uses

- Revolutionizing Motor Control: The Benefits of the SCKR1-6200 On-line Intelligent Motor Soft Starter

- FAQS

- Conclusion

- Related Posts

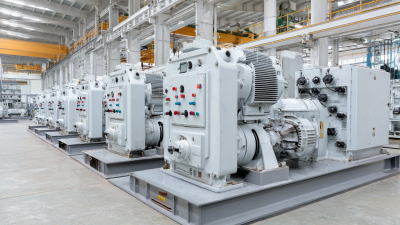

In today’s fast-changing world of industrial stuff, energy efficiency has really become more important than ever. Manufacturers are always looking for ways to run their operations smoother and cut down on energy costs — it’s a big deal. That’s where innovations like the Low Voltage Soft Starter come into play — they’re truly a game-changer.

These devices help start up electrical motors more gently, which not only makes things run more smoothly but also saves a bunch of energy. By carefully managing the voltage and current going to the motor, soft starters cut down on the mechanical stress that usually happens with direct-on-line starts. This means machines last longer and maintenance costs don’t pile up as fast.

These devices help start up electrical motors more gently, which not only makes things run more smoothly but also saves a bunch of energy. By carefully managing the voltage and current going to the motor, soft starters cut down on the mechanical stress that usually happens with direct-on-line starts. This means machines last longer and maintenance costs don’t pile up as fast.

In this article, we’re going to look at how Low Voltage Soft Starters can really boost energy efficiency in industrial settings. We’ll talk about the key benefits — like lowering the starting currents, reducing energy use during operation, and generally making the whole system more reliable. Plus, I’ll share some practical tips on how to actually implement these soft starters across various industrial applications, so businesses can really get the most out of this tech and save energy. So, let’s dive in and see how Low Voltage Soft Starters are reshaping the industry, and what steps companies can take to make the most of them.

Benefits of Low Voltage Soft Starters in Reducing Energy Consumption

Low voltage soft starters have become a key component in enhancing energy efficiency within industrial applications. By gradually ramping up the motor speed during start-up, they effectively minimize inrush current and mechanical stress on equipment. This controlled acceleration not only extends the lifespan of machinery but also significantly reduces energy consumption during the critical initial phase of operation. As industries strive for sustainability, adopting low voltage soft starters represents a strategic move towards optimizing energy use and lowering operational costs.

At Zhejiang Chuanken Electric Co., Ltd., we pride ourselves on being at the forefront of industrial automation control solutions. With 15 years of production history and a commitment to innovation, our soft starters are designed to deliver reliable performance while promoting energy efficiency. By incorporating advanced technology in our products, we help industries not only save on energy bills but also contribute to a greener environment, aligning with the global push for sustainable industrial practices.

Energy Efficiency Improvement with Low Voltage Soft Starters

Real-World Case Studies: Energy Savings with Soft Starters in Manufacturing

The integration of low voltage soft starters in manufacturing has proven efficient in enhancing energy savings, particularly through various real-world case studies. For instance, a recent analysis highlighted a beverage factory that adopted IoT-enabled sensing technology. The implementation led to a remarkable reduction in energy consumption, showcasing how real-time data collection can optimize equipment performance and energy use. According to industry reports, companies utilizing soft starters have reported energy savings of up to 30%, significantly impacting their operational costs.

Furthermore, as industries increasingly focus on energy efficiency, the role of advanced technologies cannot be overstated. Emerging technologies, such as smart software tools for energy management, facilitate the identification of energy-saving upgrade opportunities. These tools are pivotal as they assist organizations in analyzing their energy use patterns, leading to informed decisions on upgrades that can yield substantial financial benefits. With the global push towards renewable energy and smart manufacturing, the synergy between soft starters and advanced data analytics is set to redefine energy management practices in industrial applications.

Understanding the Mechanism of Soft Starters for Improved Motor Efficiency

Low voltage soft starters have become essential tools in enhancing motor efficiency within industrial applications. These devices utilize a controlled starting mechanism that gradually ramps up the motor's voltage, allowing for smoother acceleration and reduced mechanical stress on the connected equipment. By mitigating the high inrush currents typically associated with direct-on-line starting, soft starters not only protect the motor from damage but also significantly improve the overall energy efficiency of the system.

The mechanism behind soft starters hinges on their ability to control the voltage and current supplied to the motor. By employing solid-state technology, these starters enable precise adjustments in motor operation. This control results in lower energy consumption during startup phases, which can be substantial in large-scale industrial applications where motors are frequently employed. Additionally, by reducing the peak power demand, soft starters help in optimizing energy usage throughout the entire operational cycle, illustrating their crucial role in enhancing the efficiency of industrial motors.

How Low Voltage Soft Starters Enhance Energy Efficiency in Industrial Applications

| Application Area | Energy Saving (%) | Motor Start Current Reduction (%) | Payback Period (Months) | Typical Motor Size (kW) |

|---|---|---|---|---|

| Pumps | 20-30% | 50-70% | 6 | 5-200 |

| Conveyors | 15-25% | 40-60% | 8 | 3-100 |

| Fans | 10-20% | 30-50% | 5 | 0.5-50 |

| Compressors | 30-40% | 60-80% | 12 | 10-300 |

Comparative Analysis: Soft Starters vs. Traditional Starting Methods

Low voltage soft starters significantly enhance energy efficiency in industrial applications by offering a more controlled method of starting electric motors. Unlike traditional starting methods, which typically draw a large inrush current upon startup, soft starters reduce this surge by gradually ramping up the voltage and current. This controlled acceleration minimizes the mechanical stress on equipment and decreases energy consumption during the startup phase, leading to substantial energy savings over time.

A comparative analysis reveals that traditional starting methods, such as direct-on-line (DOL) starters, often result in excessive energy usage and wear on motor components due to abrupt changes in speed and torque. In contrast, soft starters not only improve energy efficiency but also extend the lifespan of motors and connected machinery. By reducing maintenance requirements and downtime associated with wear and tear, soft starters present a compelling case for industries looking to optimize their operational costs and environmental impact while enhancing the overall reliability of their systems.

Future Trends: Innovations in Soft Starter Technology for Industrial Uses

The landscape of industrial motor control is evolving with the introduction of advanced soft starter technologies aimed at enhancing energy efficiency. Future trends indicate a shift towards smarter, more integrated systems that leverage IoT (Internet of Things) capabilities. These innovations enable real-time monitoring and data analytics, allowing industries to optimize their operations by identifying energy consumption patterns and operational inefficiencies. This real-time feedback not only enhances performance but also helps in predictive maintenance, reducing unexpected downtime and extending equipment life.

Moreover, the development of adaptive algorithms in soft starters represents a significant leap forward. These algorithms can automatically adjust the starting parameters based on load conditions, which minimizes stress on motors and reduces energy consumption. Another promising trend is the integration of renewable energy sources, where soft starters can facilitate the smooth integration of solar and wind power into conventional systems. As industries strive for sustainability, these advancements in soft starter technology will play a pivotal role in reducing carbon footprints and achieving energy efficiency in industrial applications.

Revolutionizing Motor Control: The Benefits of the SCKR1-6200 On-line Intelligent Motor Soft Starter

In the ever-evolving landscape of industrial automation, the SCKR1-6200 on-line intelligent motor soft starter emerges as a game-changer, particularly in enhancing motor control efficiency. With six distinctive starting modes and twelve robust protection functions, this innovative device caters to a wide range of applications, ensuring optimal performance and reliability. According to a report by the International Electrotechnical Commission (IEC), smart motor control solutions can reduce energy consumption by up to 30%, confirming the necessity for advanced technology in modern machinery.

The versatility of the SCKR1-6200 also extends to its two vehicle modes, which provide tailored startup and running conditions for various types of motors. This adaptability is critical, as different motor configurations often require unique control strategies to maximize efficiency and lifespan. A study published by the Institute of Electrical and Electronics Engineers (IEEE) highlights that precise motor control can improve an equipment's operational longevity by as much as 40%, reducing downtime and maintenance costs significantly.

Furthermore, the integration of intelligent features in the SCKR1-6200 empowers operators with enhanced monitoring capabilities. Real-time data analytics on motor performance not only aid in proactive maintenance strategies but also facilitate better decision-making. As industries increasingly shift towards smart manufacturing, the SCKR1-6200 positions itself as an essential component for businesses striving to maintain competitive advantages through technology and innovation.

FAQS

: Soft starters are low voltage devices that control the voltage and current supplied to electric motors, allowing for a gradual increase in power during startup. This minimizes inrush currents and mechanical stress, leading to improved energy efficiency and reduced operational costs.

Companies that utilize soft starters have reported energy savings of up to 30%, significantly impacting their operational costs through enhanced efficiency.

IoT-enabled sensing technology facilitates real-time data collection and analysis, optimizing equipment performance and energy use, as demonstrated by various real-world case studies, such as those in beverage factories.

Soft starters prevent damage to motors by gradually ramping up the voltage, thereby avoiding the high inrush currents associated with direct-on-line starting methods, which can cause premature wear and failure.

Smart software tools help organizations analyze energy use patterns and identify opportunities for energy-saving upgrades, leading to informed decision-making and substantial financial benefits.

Soft starters provide a controlled starting method that reduces energy consumption and mechanical stress, unlike DOL starters which can cause excessive energy usage and wear on motor components due to abrupt changes in speed and torque.

By minimizing wear and tear through controlled acceleration, soft starters extend the lifespan of motors and connected machinery, reducing maintenance requirements and downtime.

The combination of soft starters with advanced data analytics and the global shift towards renewable energy and smart manufacturing is anticipated to reshape energy management practices across various industrial applications.

Soft starters lower peak power demand during startup phases, contributing to overall optimized energy usage throughout the entire operational cycle in industrial applications.

They enhance motor efficiency, protect equipment, reduce energy consumption, and improve reliability, making them essential for industries aiming to optimize operational costs and reduce environmental impact.

Conclusion

Low Voltage Soft Starters play a crucial role in enhancing energy efficiency within industrial applications. By gradually ramping up motor speeds, these devices significantly reduce energy consumption compared to traditional starting methods. The benefits are not only theoretical; real-world case studies have demonstrated substantial energy savings in manufacturing processes, highlighting the practicality of adopting soft starters. Additionally, understanding the mechanisms behind these devices reveals how they improve motor efficiency, leading to lower operational costs.

As a company specializing in industrial automation control products for over 15 years, Zhejiang Chuanken Electric Co., Ltd. recognizes the importance of Low Voltage Soft Starters in the evolving industrial landscape. Looking ahead, innovations in soft starter technology promise to further optimize energy use and streamline operations, making them an essential component for future advancements in industrial settings.

Related Posts

-

Understanding Industry Standards for Best Soft Starter Cabinet Selection Guide

-

Essential Checklist for Choosing the Right 280kw Soft Starter for Your Business Needs

-

The Definitive Guide to Selecting the Perfect 280kw Soft Starter for Your Global Sourcing Needs

-

Mastering the Installation of 250kw Soft Starters A Step by Step Guide for Global Buyers

-

5 Reasons Why 115kw Soft Starters Boost Industrial Efficiency by Over 30 Percent

-

Unlocking Motor Efficiency: How Bypass Soft Starters Revolutionize Industrial Applications