How to Choose the Best VFD Drive Manufacturers for Your Business Needs

Table of Contents

- Understanding VFD Drives and Their Importance in Industry

- Key Factors to Consider When Choosing VFD Drive Manufacturers

- Evaluating Manufacturer Reputation and Industry Experience

- Comparing Product Range and Customization Options

- Assessing Technical Support and Customer Service Quality

- Analyzing Cost vs. Value in VFD Drive Offerings

- Reading Customer Reviews and Case Studies for Insights

- Maximize Efficiency with the General VFD 55kw 380V 3Phase Inverter: A Comprehensive Guide to Motor Speed Control

- FAQS

- Conclusion

- Related Posts

When you're on the hunt for the right VFD drive manufacturers for your business, it’s really important to wrap your head around what makes for good performance and reliability. You see, Variable Frequency Drives—those little devices—are pretty much the backbone of many industrial setups, giving you this awesome control over motor speed and torque. With everyone pushing for energy efficiency and more automation these days, picking the right manufacturer can totally boost your operations—not to mention save you some cash in the long run.

Figuring out which VFD manufacturer is a good fit starts with knowing your specific needs—think about your load types and the environment where they’ll be used. Good manufacturers will offer a variety of products suited to different situations, along with solid customer support and technical help. It’s also worth considering how durable their products are, how easily they can be integrated into your systems, and whether they stick to industry standards. All these things matter because they show who truly cares about quality, innovation, and providing reliable gear.

In the end, making a smart choice when picking your VFD supplier sets a strong foundation for your business to succeed. Take your time to do some homework on your potential partners—trust me, it pays off. That way, you can boost your productivity and feel confident you’re investing in technology that keeps your operations running smoothly.

Understanding VFD Drives and Their Importance in Industry

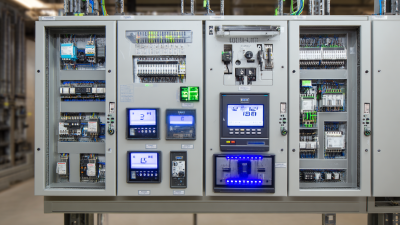

Variable frequency drives (VFDs) play a crucial role in the industrial landscape by controlling the speed and torque of electric motors. This capability not only enhances the efficiency of machinery but also contributes significantly to energy savings. By allowing for precise speed adjustments, VFD drives can optimize the performance of various applications, such as pumps, conveyor systems, and fans. As industries increasingly prioritize sustainability and reduce operational costs, the importance of VFDs becomes even more apparent.

In addition to energy efficiency, VFDs offer greater control and flexibility in industrial processes. They provide the ability to start and stop equipment gradually, minimizing mechanical stress and extending the life of motors and other mechanical components. Furthermore, VFDs can be integrated with automation systems, enabling sophisticated monitoring and management of manufacturing processes. As a result, understanding the significance of VFD drives is essential for businesses aiming to enhance operational performance and remain competitive in today's evolving market.

Key Factors to Consider When Choosing VFD Drive Manufacturers

When selecting a Variable Frequency Drive (VFD) manufacturer for your business, several key factors should guide your decision-making process. First and foremost, assess the manufacturer's reputation and experience in the industry. A well-established company with a proven track record is likely to provide higher quality products and better customer support. Look for manufacturers that specialize in your specific application, as their expertise will ensure that the VFDs are tailored to meet the unique demands of your operations.

Another critical factor to consider is the range of products offered by the manufacturer. A diverse product line allows for greater flexibility in choosing a VFD that suits your particular needs. It's also essential to evaluate the technical support and service level provided by the manufacturer. Good technical support can be invaluable, especially during the installation and commissioning phases, ensuring that any issues are promptly addressed. Additionally, consider the availability of spare parts and the manufacturer's commitment to after-sales service, as this can significantly impact the reliability and longevity of your VFDs.

Evaluating Manufacturer Reputation and Industry Experience

When selecting a variable frequency drive (VFD) manufacturer for your business, evaluating the manufacturer's reputation and industry experience is crucial. A strong reputation often indicates reliability and quality, as well-established companies typically have a track record of meeting customer expectations. Look for manufacturers with positive reviews and case studies that demonstrate success in your specific industry. Engaging with industry forums or discussion groups can also provide insights into a manufacturer’s credibility and customer satisfaction.

Tips: Always check customer testimonials and seek out feedback from current users. Consider reaching out to other businesses in your sector to understand their experiences. Additionally, reviewing professional certifications or partnerships can further validate a manufacturer’s standing in the industry.

Industry experience is another key factor to consider. Manufacturers that have operated for several years are likely to have confronted a range of challenges, which can lead to improved product development and customer service. Their longevity often translates to a deeper understanding of industry-specific needs and technological advancements.

Tips: Investigate how long the manufacturer has been in business and their history in your industry. Look for any innovations they’ve pioneered or significant advancements they’ve contributed to the VFD field. Furthermore, consider their engagement in ongoing research and development, as this reflects their commitment to adapting to changing market demands.

Comparing Product Range and Customization Options

When selecting a Variable Frequency Drive (VFD) manufacturer, it's essential to evaluate both the product range and customization options available. A diverse product range allows businesses to select drives that precisely meet their operational requirements. This includes evaluating the drive's power ratings, control methods, and compatibility with different motor types. Manufacturers offering a wide variety of VFDs tend to have better expertise and support systems in place, making it easier to find a product that aligns with specific applications.

Customization options play a crucial role in ensuring that the VFD meets unique business needs. Many manufacturers provide customizable features such as specific programming capabilities, communication protocols, and physical configurations. This level of customization can significantly enhance operational efficiency and adaptability, allowing businesses to tailor the VFD to specific processes or integration with other systems. When assessing potential manufacturers, inquire about their willingness to work with clients on developing specialized features or solutions, as this can be a determining factor in achieving optimal performance from your drive systems.

Comparison of VFD Drive Product Range and Customization Options

Assessing Technical Support and Customer Service Quality

When selecting the best VFD drive manufacturers for your business needs, assessing the quality of technical support and customer service is paramount. A manufacturer’s ability to provide prompt and effective support can significantly impact your operations, especially when dealing with complex systems. It is essential to evaluate whether they offer multiple channels for assistance, such as phone support, email, or live chat, and the responsiveness of their team. Additionally, consider their availability for on-site support or consultations, which can be crucial in troubleshooting and optimizing the performance of VFDs.

Moreover, the quality of customer service extends beyond initial support; it also encompasses the training and resources available for your team. Manufacturers that provide comprehensive documentation, online tutorials, or training programs can facilitate smoother implementation and operation of the VFD drives. Customer feedback and reviews about their service interactions can offer valuable insights into the reliability and effectiveness of the manufacturer's support system. Ultimately, a manufacturer committed to high-quality technical assistance and customer service will not only enhance your experience but also ensure that your VFD systems operate efficiently and effectively over time.

Analyzing Cost vs. Value in VFD Drive Offerings

When evaluating VFD (Variable Frequency Drive) offerings, it is essential to weigh cost against value. The initial price tag of a VFD can be misleading; lower-cost models may lack the performance, durability, or features that are crucial for long-term operational efficiency. Businesses should consider the total cost of ownership, which includes installation, maintenance, and energy savings over time, rather than simply focusing on the upfront cost. A more expensive drive may offer superior energy efficiency, advanced features, and a longer lifespan, ultimately saving money in the long run.

Moreover, assessing the value of VFD offerings involves looking beyond mere functionality. Factors such as customer support, warranty terms, and the manufacturer’s reputation for reliability should be considered. A manufacturer that invests in customer service can significantly enhance the user experience, helping businesses troubleshoot issues quickly. Additionally, a robust warranty can minimize risk, guarding against potential losses due to equipment failure. In this way, the right VFD can translate into not only improved performance but also peace of mind, making the investment worthwhile despite a higher initial cost.

Reading Customer Reviews and Case Studies for Insights

When selecting the best VFD (Variable Frequency Drive) manufacturers for your business, delving into customer reviews and case studies can provide invaluable insights. Customer reviews often reveal firsthand experiences regarding product performance, reliability, and user satisfaction. By analyzing these reviews, potential buyers can gauge how the VFDs have performed in real-world applications. Particular attention should be paid to recurring themes, such as ease of installation, energy efficiency, and technical support, as these insights can significantly influence the overall value a manufacturer brings to the table.

Case studies serve as practical examples of how VFDs have been successfully integrated into various industries. They often highlight the challenges faced by different businesses and how specific manufacturers' solutions addressed those obstacles. By examining these case studies, prospective buyers can identify which manufacturers have a proven track record in their specific sector or application. Furthermore, it is beneficial to evaluate the results achieved, such as improvements in operational efficiency, cost savings, and any innovative approaches that were employed. This information allows businesses to make informed decisions, ensuring that their chosen VFD manufacturer can meet their unique demands effectively.

Maximize Efficiency with the General VFD 55kw 380V 3Phase Inverter: A Comprehensive Guide to Motor Speed Control

Motor speed control is paramount in enhancing operational efficiency across various industries. The General VFD 55kw 380V 3Phase Inverter stands out as an exceptional solution, enabling precise management of motor speeds. This innovative device allows users to optimize energy consumption, thus potentially reducing operational costs by up to 30%. According to a report from the International Energy Agency, effectively controlling motor speed can lead to significant electricity savings, underscoring the importance of modern variable frequency drives in industrial applications.

The SHCKELE SCK300 inverter, featuring an 18-month warranty, exemplifies the reliability and robustness expected in today’s competitive landscape. By employing advanced control techniques and comprehensive user interfaces, this general-type inverter simplifies the process of adjusting speeds, thereby enhancing productivity. The integration of such technology has been shown to reduce mechanical stress on motors, prolonging their lifespan and resulting in lower maintenance costs, which is crucial for businesses aiming for sustainable practices.

In addition, industry data suggests that implementing variable frequency drives can improve system reliability and decrease downtime. With the agility to adjust motor speed based on real-time demands, industries such as manufacturing, HVAC, and water treatment can experience enhanced performance and resource management. Embracing these technological advancements enables companies to maintain a competitive edge while contributing positively to their economic and environmental objectives.

FAQS

: It's important to evaluate the product range, customization options, technical support, and customer service quality offered by the manufacturer. A diverse product range and customization capabilities allow for better alignment with specific operational requirements.

A diverse product range enables businesses to select drives that match their operational needs, including power ratings and compatibility with different motor types, which is crucial for optimal performance.

Customization options can enhance operational efficiency and adaptability by allowing businesses to tailor the VFD to unique processes or systems, ensuring it meets specific business needs.

Assess the availability of multiple support channels (phone, email, live chat), the responsiveness of their support team, and whether they offer on-site assistance for troubleshooting and optimization.

Good customer service is essential as it includes training, comprehensive documentation, and resources that can facilitate smoother implementation and ongoing operation of the VFD systems.

Consider the total cost of ownership, which includes installation, maintenance, and expected energy savings, rather than just the initial price. Assess how performance and durability may affect long-term operational efficiency.

Consider customer support quality, warranty terms, and the manufacturer's reputation for reliability, as these factors can significantly influence the overall user experience and investment risk.

A higher-priced VFD may offer better energy efficiency, advanced features, and a longer lifespan, which can lead to savings over time and enhanced performance, making the investment worthwhile despite an initial higher cost.

Conclusion

When selecting the best VFD drive manufacturers for your business needs, it’s essential to understand the role of VFD drives in industrial applications. These drives are crucial for controlling motor speed and improving energy efficiency, thus highlighting their significance in various sectors. Key factors to consider include the manufacturer's reputation, industry experience, and the range of products they offer, including customization options.

Additionally, assessing the quality of technical support and customer service is vital, as these elements can significantly impact your operational efficiency. Analyzing the cost versus value of VFD drive offerings will help ensure you make a sound financial decision. Finally, reading customer reviews and case studies can provide valuable insights into the reliability and performance of potential manufacturers, allowing you to choose the best VFD drive manufacturer to suit your specific requirements.

Related Posts

-

Top Strategies for Optimizing Vfd 5.5kw Performance in Your Operations

-

Innovative Applications of Vfd 220 380 in Modern Industrial Automation

-

2025 Guide: How to Choose the Right VFD Frequency Drive for Your Needs

-

Unlocking Growth in China's Vfd Single Phase To 3 Phase Market Insights from 2025 Canton Fair

-

5 Reasons Why the 0.75kw Vfd is the Best Choice for Your Industrial Needs

-

Essential Checklist for Choosing the Right 280kw Soft Starter for Your Business Needs