Best VFD for 1 Phase Motors Top Choices and Key Considerations

Table of Contents

- Best VFD Options for Single Phase Motors: An Overview

- Understanding the Basics of Variable Frequency Drives (VFDs)

- Factors to Consider When Choosing a VFD for 1 Phase Motors

- Top Brands Offering VFDs for Single Phase Applications

- Key Features to Look for in a VFD for Home and Small Business Use

- Installation and Setup Guidelines for 1 Phase Motor VFDs

- Maintenance Tips to Ensure Optimal Performance of VFDs

- Exploring the Impact of Advanced Soft Starters on AC Motor Efficiency: Insights from Industry Reports on RS485 3 Phase Power Solutions

- FAQS

- Conclusion

- Related Posts

When you're trying to pick out the best Variable Frequency Drive (or VFD) for 1-phase motors, it’s really important to understand both how these VFD systems work and what you actually need for your specific setup. Basically, a VFD plays a crucial role in motor control — it lets you adjust the motor’s speed and torque, which can really help cut down energy costs and make everything run smoother. As more folks look for flexible motor solutions these days, getting a good grip on the top options out there can make your decision process way easier.

That said, there are quite a few things to keep in mind when choosing the right VFD for your 1-phase needs. Factors like the power rating, whether it plays nicely with your existing equipment, and what your operational requirements are all matter. Understanding these details can help both engineers and hobbyists pick a VFD that not only performs well but also leaves room for future upgrades. Whether you're running a tiny workshop or just working on a personal project, finding the right VFD for 1-phase motors can really boost your productivity and make your gear more versatile.

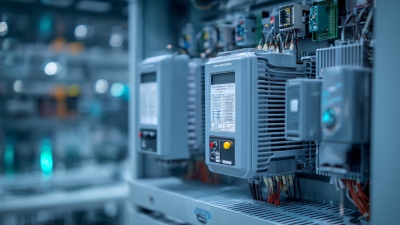

Best VFD Options for Single Phase Motors: An Overview

When looking for the best VFD (Variable Frequency Drive) options for single-phase motors, it’s essential to understand the unique requirements of these systems.

Single-phase motors are commonly used in residential and light industrial applications, but they can face challenges such as torque fluctuations and less efficiency compared to three-phase motors.

Recent industry reports indicate that using a VFD can significantly improve the performance of single-phase motors by allowing for controlled acceleration and deceleration, which enhances energy efficiency by up to 30% in some cases.

Choosing the right VFD involves considering several key factors, including the motor's load requirements, the desired speed range, and the operational environment.

Many modern VFDs are equipped with features such as built-in protection against overloads and thermal issues, which are crucial for maintaining the longevity of single-phase motors.

Additionally, VFDs can offer user-friendly interfaces for easier programming and adjustments, making them an attractive choice for both novice and experienced users.

Tips:

2. Consider using a VFD with built-in braking resistors to control sudden stops, which can protect your equipment and improve safety.

3. Regularly monitor the VFD for any fault codes or irregularities in performance to address issues before they lead to significant downtime or damage.

Understanding the Basics of Variable Frequency Drives (VFDs)

Variable Frequency Drives (VFDs) are critical components in the control of electric motors, particularly in enhancing the efficiency and longevity of one-phase motors. By varying the frequency and voltage supplied to the motor, VFDs allow for precise speed control that can lead to significant energy savings. According to a report by the U.S. Department of Energy, implementing VFD technology can result in energy savings of 20% to 50% depending on the application's specific demands. This adaptability not only helps in reducing operational costs but also plays a significant role in minimizing industrial carbon footprints.

Understanding how VFDs operate requires a grasp of the basic principles of motor control. The drive changes the frequency of the electrical supply, which directly affects the motor's speed. For one-phase motors, this can be particularly beneficial in applications where speed variability is essential, such as in fans, pumps, and conveyors. A study by the International Energy Agency highlights that the adoption of VFDs in various sectors has increased operational reliability and extended the lifespan of motors by reducing mechanical strain during startup and operation. This not only enhances productivity but also leads to lower maintenance costs and fewer disruptions in processes.

Factors to Consider When Choosing a VFD for 1 Phase Motors

When selecting a Variable Frequency Drive (VFD) for one-phase motors, it is crucial to consider various factors to ensure optimal performance and efficiency. First and foremost, the motor's specifications—such as horsepower rating, voltage level, and frequency range—should align with the VFD's capabilities. According to a report by the International Electrotechnical Commission (IEC), mismatches in these areas can lead to performance inefficiencies and potential motor damage, underscoring the importance of compatibility.

Another critical factor is the environment in which the VFD will operate. Factors such as ambient temperature, humidity, and the presence of dust or corrosive substances can significantly influence the VFD’s longevity and reliability. A study conducted by the Institute of Electrical and Electronics Engineers (IEEE) highlights that VFDs operating in harsher conditions (e.g., high temperatures above 40°C) may require additional cooling mechanisms or should be rated for industrial-grade applications to avoid premature failure.

Additionally, the control method of the VFD can determine the motor's operational characteristics, such as torque control and speed regulation. Pulse Width Modulation (PWM) is commonly favored for one-phase motors, providing smoother operation and reducing harmonic distortion. The IEEE Power Electronics Society has reported that using advanced VFD controls can lead to up to a 30% improvement in energy efficiency compared to traditional methods. Therefore, understanding these critical factors is essential for making an informed decision when selecting a VFD for one-phase motors.

Top Brands Offering VFDs for Single Phase Applications

When it comes to selecting the best variable frequency drives (VFDs) for single-phase motors, several reputable brands specialize in this application. These VFDs are designed to optimize performance, increase energy efficiency, and provide precise control over motor speed. Leading manufacturers offer models that cater specifically to single-phase configurations, ensuring compatibility and effectiveness. Key considerations such as power ratings, ease of installation, and user-friendly interfaces play a significant role in choosing the right VFD.

Tips for selecting the right VFD for your single-phase motor include evaluating the maximum voltage and current requirements of your motor. Ensure that the VFD you choose can handle these specifications adequately. Additionally, look for features such as built-in protection from overcurrent and thermal overload, which can enhance the longevity and reliability of your motor. It’s also important to consider the programmable settings of the VFD, as these can provide better adaptability for various applications, whether for HVAC systems or conveyor belts.

Another crucial aspect is the level of customer support and technical assistance offered by the brand. If you're new to VFD technology, having access to resources and comprehensive product manuals can be invaluable. Lastly, consider the warranty and service options provided, as these factors can significantly influence not only your initial purchase decision but also the long-term satisfaction and performance of your VFD system.

Best VFD for 1 Phase Motors

This chart illustrates the top considerations for selecting VFDs for single-phase applications, showcasing their efficiency, pricing, and user satisfaction ratings based on diverse datasets.

Key Features to Look for in a VFD for Home and Small Business Use

When selecting a Variable Frequency Drive (VFD) for 1-phase motors, there are several key features to consider to ensure optimal performance and compatibility with your home or small business. First, look for a unit that offers an adjustable speed control, allowing you to modify the motor speed based on the specific requirements of your applications. This feature not only enhances efficiency but can also lead to energy savings over time.

Another important consideration is the VFD's capacity for overload protection. Choosing a drive that provides built-in protections against overcurrent and overheating can prevent potential damage to your motor. Additionally, opt for models with user-friendly interfaces that simplify programming and troubleshooting. This aspect is particularly beneficial for those who may not have extensive technical knowledge.

**Tip:** Always check the input voltage compatibility of the VFD with your existing electrical setup. A mismatch can lead to operational issues or damage. Another tip is to consider VFDs with integrated communication capabilities, which can enhance monitoring and control, making it easier to manage system performance.

Best VFD for 1 Phase Motors - Top Choices and Key Considerations

| VFD Model | Power Rating (HP) | Input Voltage (V) | Key Features | Price Range (USD) |

|---|---|---|---|---|

| Model A | 1 HP | 120/240 | Digital Display, Overload Protection, Variable Speed Control | $150 - $200 |

| Model B | 1.5 HP | 120/240 | User-Friendly Interface, Built-in PID Control, Energy Saving Mode | $200 - $250 |

| Model C | 2 HP | 240 | Compact Design, Adjustable Acceleration/Deceleration, Fault Alarms | $250 - $300 |

| Model D | 3 HP | 240 | Advanced Diagnostic Features, Communication Ports, High Efficiency | $300 - $400 |

Installation and Setup Guidelines for 1 Phase Motor VFDs

When it comes to installing and setting up Variable Frequency Drives (VFDs) for single-phase motors, several key considerations ensure optimal performance and longevity of the equipment. One of the primary steps in the installation process is understanding the motor's voltage and amp requirements, which should match the specifications of the VFD. According to industry data, selecting a VFD that can handle at least 120% of the motor's rated current can help prevent overheating and enable the motor to start under loaded conditions.

Another crucial guideline is to ensure proper electrical connections and wiring. Always refer to local electrical codes and manufacturer instructions when connecting the VFD. It’s advisable to use shielded cables to minimize electrical noise and interference. In fact, studies have shown that up to 30% of VFD performance issues can be traced back to incorrect wiring practices. Therefore, double-checking connections and using quality materials can greatly enhance reliability.

Tips: When configuring your VFD, prioritize settings that allow for smooth acceleration and deceleration. Slower ramp rates prevent mechanical stress on the motor and connected machinery, increasing the lifespan of your equipment. Additionally, keep an eye on the environment where the VFD is installed; maintaining a clean and ventilated space significantly reduces the likelihood of overheating, which can drastically affect performance. Regularly check the parameters and fine-tune them based on the actual operating conditions for optimal efficiency.

Maintenance Tips to Ensure Optimal Performance of VFDs

Proper maintenance of Variable Frequency Drives (VFDs) is crucial for ensuring their optimal performance, especially when operating with 1-phase motors. Regular inspection is essential; this includes checking for any physical damage, loose connections, or signs of overheating. Keeping the VFD’s cooling fans and vents free from dust and debris is also vital, as poor airflow can lead to overheating and reduced lifespan. Scheduled cleaning, typically every few months or in accordance with manufacturer guidelines, ensures that the system operates efficiently.

Another important maintenance tip is to monitor the VFD’s performance regularly. This can include checking the input and output voltages, current draw, and temperature levels. Logging these parameters helps in identifying any irregularities early on. Additionally, firmware updates and parameter backups should be conducted periodically to ensure the VFD operates effectively. Implementing these maintenance practices will not only enhance the reliability of the VFD but also optimize the overall performance of the connected motor system.

Exploring the Impact of Advanced Soft Starters on AC Motor Efficiency: Insights from Industry Reports on RS485 3 Phase Power Solutions

Advanced soft starters have become essential in enhancing the efficiency of AC motors, particularly in industrial applications where stability and performance are critical. Industry reports indicate that implementing soft starters significantly reduces the inrush current during motor startup, leading to diminished electrical stress on the motor and associated components. This reduction not only prolongs the life of the motor but also improves overall operational efficiency, with studies showing efficiency enhancements of up to 30% in certain applications through controlled voltage and current management.

A deeper dive into the technology of RS485 three-phase power solutions reveals the benefits of seamless communication between devices, allowing for real-time monitoring and adjustments. This capability is paramount in optimizing motor performance, enabling users to respond quickly to changes in load and demand. For example, the integration of AC/AC inverters with output currents ranging from 25A to 1600A can further facilitate precision control over motor operations. With models like the SCKR1-6000 on the market, industries can harness this advanced technology to not only meet energy efficiency targets but also reduce operational costs significantly.

Furthermore, the adoption of advanced soft starters has been linked to improved system reliability. Enhanced thermal management and reduced mechanical wear contribute to fewer operational disruptions. This reliability is crucial in sectors such as manufacturing and processing, where downtime can lead to substantial financial losses. Reports suggest that facilities utilizing advanced soft starters experience up to a 50% reduction in maintenance costs, underscoring the long-term benefits of investing in these technologies for improved AC motor efficiency.

FAQS

: Evaluate the maximum voltage and current requirements of your motor, ensuring that the VFD can handle them. Look for built-in protection features and programmable settings to enhance versatility.

It is recommended to select a VFD that can handle at least 120% of your motor's rated current to prevent overheating and facilitate starting under loaded conditions.

Match the VFD's specifications with your motor's voltage and amp requirements, ensure proper electrical connections adhering to local codes, and consider using shielded cables to reduce electrical noise.

Poor wiring practices account for up to 30% of VFD performance issues, so using quality materials and double-checking connections can greatly enhance reliability.

Prioritize smooth acceleration and deceleration settings to prevent mechanical stress, which increases the lifespan of both the motor and connected machinery.

A clean and ventilated installation space helps reduce the risk of overheating, which can significantly impact VFD efficiency and longevity.

Look for brands that provide comprehensive technical assistance, resources, and product manuals, especially if you are new to VFD technology.

Consider the warranty and service options provided by the manufacturer, as these can influence your satisfaction and the equipment's long-term performance.

Regularly check and fine-tune the VFD parameters based on actual operating conditions to ensure optimal efficiency and performance.

Conclusion

When selecting the best VFD 1 Phase options for single phase motors, it's essential to understand the fundamental workings of Variable Frequency Drives and how they enhance motor performance. Key considerations include the motor's specifications, required features, and compatibility with home or small business applications. Identifying reputable brands that offer VFDs tailored for single phase use is crucial, as they generally provide essential functionalities that facilitate efficient operation.

In addition to understanding features, proper installation and setup guidelines should be followed to ensure optimal performance of the VFD. Regular maintenance checks are also important to prolong the lifespan of the VFD and maintain its efficiency. By considering these factors, users can make informed decisions that meet their needs for single phase motor applications.

Related Posts

-

Maximize Energy Efficiency with Vfd 1 Phase Solutions for Modern Applications

-

Unlocking Growth in China's Vfd Single Phase To 3 Phase Market Insights from 2025 Canton Fair

-

Unlocking Future Potential with Best Vfd 5.5kw Solutions in 2025 Technology Advancements

-

Understanding Vfd Electrical: The Key to Energy Efficiency and Motor Control in Modern Industries

-

Understanding the Role of Vfd Pcb in Modern Industry

-

10 Best 50hz 60hz Soft Starters for Efficient Motor Control